Fluoroplastic magnetic pumps are highly efficient pumping devices used for transferring corrosive liquids, widely applied in petrochemical, biopharmaceutical, new energy, and environmental protection industries. Understanding its internal structure and working principle is crucial for its use and maintenance. This article provides a detailed introduction to the structure of fluoroplastic magnetic pumps, complete with a structural diagram analysis, to help users better understand and use this equipment.

I. Basic Components of the Fluoroplastic Magnetic Pump

Pump Body

The pump body is primarily made of fluoroplastic material, offering excellent corrosion resistance against strong acids, alkalis, and other corrosive liquids. It is designed as a single piece to ensure structural integrity and sealing.

Impeller

The impeller is the core component of the pump, used for accelerating and transferring liquids. The impeller of a fluoroplastic magnetic pump typically features a closed design to enhance efficiency and durability.

Magnetic Drive Assembly

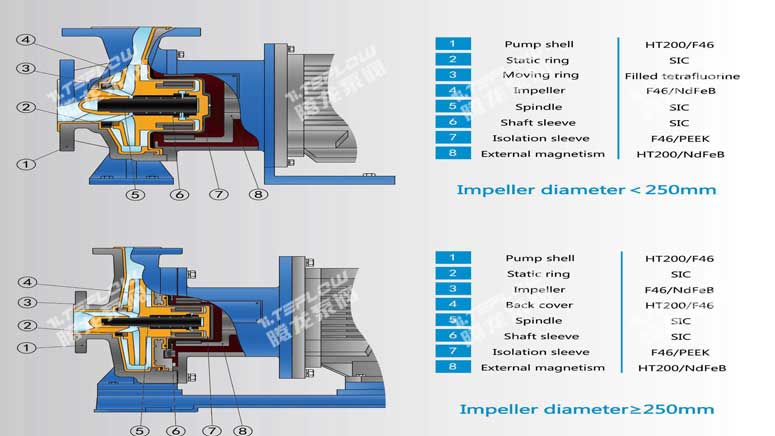

The magnetic drive assembly consists of an inner magnetic rotor and an outer magnetic rotor. It drives the impeller through magnetic coupling, eliminating the leakage issues found in traditional pumps. The outer magnetic rotor is connected to the motor, while the inner magnetic rotor is connected to the impeller, separated by an isolation sleeve.

Isolation Sleeve

The isolation sleeve is installed between the inner and outer magnetic rotors, made from fluoroplastic or other corrosion-resistant materials to prevent liquid leakage and protect the magnetic drive assembly.

Bearing

Bearings are typically made from corrosion-resistant materials such as silicon carbide or ceramics, ensuring long-term stable operation in corrosive environments. They support and fix rotating components, reducing friction and wear.

II. Detailed Explanation of the Fluoroplastic Magnetic Pump Structure Diagram

Below is a typical structural diagram of a fluoroplastic magnetic pump:(Insert actual structural diagram with labeled )

Pump Body

The outer shell of the pump, primarily responsible for bearing pressure and liquid, usually made from PVDF or PTFE.

Impeller

Rotates through internal magnetic drive to achieve liquid transfer.

Inner Magnetic Rotor

Fixed to the impeller and driven directly by the outer magnetic rotor.

Outer Magnetic Rotor

Driven by the motor, generating a magnetic field to act on the inner magnetic rotor.

Isolation Sleeve

Placed between the inner and outer magnetic rotors, isolating the liquid and magnetic drive components.

Bearing

Supports rotating components, reduces friction, and extends service life.

III. Working Principle of the Fluoroplastic Magnetic Pump

The working principle of a fluoroplastic magnetic pump is based on magnetic coupling drive. The motor drives the outer magnetic rotor to rotate, whose magnetic field acts through the isolation sleeve on the inner magnetic rotor. The inner magnetic rotor is fixed to the impeller, thereby driving the impeller to rotate and achieve liquid transfer. This design avoids the shaft seal problems of traditional pumps, completely eliminating the possibility of leakage.

IV. Advantages of the Fluoroplastic Magnetic Pump

Strong Corrosion Resistance

Made from fluoroplastic material, it resists various corrosive media, suitable for harsh environments such as chemical industries.

Leak-proof Design

The magnetic drive and isolation sleeve design completely prevent liquid leakage, ensuring safety and environmental protection.

Easy Maintenance

Simple structure, easy disassembly, and low daily maintenance costs.

High Efficiency and Energy Saving

The efficient impeller design improves pump performance and reduces energy consumption.

V. Applications of the Fluoroplastic Magnetic Pump

Fluoroplastic magnetic pumps are widely used in the following fields:

Petrochemical

For transferring strong acids, strong alkalis, and other corrosive liquids.

Biopharmaceutical

For transferring high-purity and highly corrosive liquids.

New Energy

For transferring corrosive liquids and chemicals.

Environmental Protection

For wastewater treatment and corrosive liquid transfer in environmental protection equipment.

Fluoroplastic magnetic pumps, with their excellent corrosion resistance and leak-proof design, have become indispensable liquid transfer equipment in many industries. This detailed explanation of the structure and principles aims to help users better understand and utilize fluoroplastic magnetic pumps, enhancing equipment longevity and operational efficiency.

For more information about fluoroplastic magnetic pumps, please visit the Anhui Tenglong Pump Valve Manufacturing Co., Ltd. official website. We are dedicated to providing you with high-quality products and services.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318