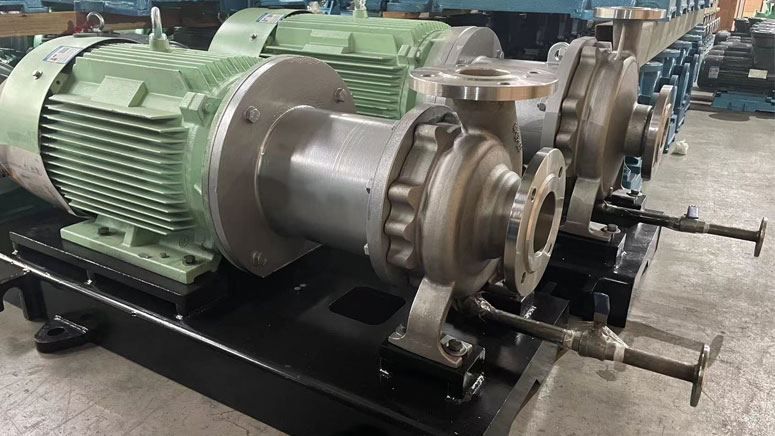

In industrial applications dealing with high-temperature liquids, stainless steel high-temperature magnetic pumps have emerged as crucial equipment due to their unique design and material properties. This article delves into the design features of stainless steel high-temperature magnetic pumps and provides a practical guide for selecting and utilizing these important pump devices.

1. Superiority of Stainless Steel Material:

Stainless steel is chosen as the manufacturing material for pump bodies and critical components, offering excellent corrosion resistance and high-temperature stability. This material selection ensures the long-term stable operation of the pump while meeting the specific requirements for handling high-temperature liquids.

2. Magnetic Transmission and Sealing Technology:

Stainless steel high-temperature magnetic pumps employ magnetic transmission technology, utilizing magnetic couplers to separate the motor from the pump body, eliminating the need for mechanical seals. This design not only enhances the reliability of the pump but also reduces the risk of leakage, especially in high-temperature environments.

3. Heat Dissipation Design and Temperature Control System:

Considering the heat generated in high-temperature environments, these pumps typically feature effective heat dissipation designs to ensure the pump operates at a normal temperature. Some advanced models also come equipped with temperature control systems, adjusting temperatures based on operational conditions to enhance equipment stability.

4. Application of High-Temperature Resistant Sealing Materials:

Critical parts of stainless steel high-temperature magnetic pumps utilize sealing materials resistant to high temperatures, ensuring effective sealing performance in high-temperature liquids. This helps prevent liquid leakage, improving the safety of the equipment.

Selection Guide:

Analysis of Liquid Properties:Thoroughly understand the temperature, viscosity, and corrosiveness of the handled liquid to determine the suitable model of stainless steel high-temperature magnetic pump.

Flow Rate and Head Requirements:Based on process demands, accurately determine the required flow rate and head to choose an appropriately sized pump model.

Consideration of Environmental Temperature:Consider the temperature of the equipment's operating environment and select a stainless steel high-temperature magnetic pump with sufficient resistance to high temperatures.

Maintenance and Operational Cost:Consider the maintenance cost and ease of maintenance, choosing a model that is easy to maintain to lower operational costs.

By gaining a comprehensive understanding of the design features of stainless steel high-temperature magnetic pumps and following a scientific selection process, users can accurately apply this critical equipment. This ensures stable and efficient operation in high-temperature environments, meeting the needs of industrial production.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318